The first time someone explained Six Sigma to me, I nodded along while secretly thinking it sounded like corporate jargon the kind of buzzword executives toss around to sound impressive. This article explores how Six Sigma process improvement methodology delivers measurable results across industries, from manufacturing to healthcare and beyond.

That dismissive attitude lasted until I witnessed a Six Sigma project eliminate a recurring manufacturing defect that had plagued our facility for years. Watching a structured methodology solve what seemed unsolvable converted me from skeptic to believer almost overnight.

What exactly changed my mind? It was watching a team refuse to guess. They did not rely on the operator with thirty years of experience, though they certainly listened to him. They did not jump to the easiest explanation.

Instead, they gathered data points like someone collecting evidence for a courtroom trial. When they finally traced the defect to a subtle temperature fluctuation during a specific shift change, I remember thinking: We would never have found this through intuition alone.

Six Sigma is a set of techniques and tools for process improvement introduced by engineer Bill Smith at Motorola in 1986. But knowing that definition does not prepare you for what it actually feels like to participate in a Six Sigma project. The methodology seeks to improve quality by identifying and removing causes of defects while minimizing variability in processes.

The term itself originates from statistical quality control, referring to the fraction of a normal curve that lies within six standard deviations of the mean which sounds complicated until you realize it simply means aiming for near-perfection. What distinguishes Six Sigma from earlier quality improvement initiatives is its commitment to data-driven decision making rather than assumptions.

How many times have you sat in a meeting where someone proposed a solution based on how things felt? I have lost count. Every Six Sigma project follows a defined methodology with specific value targets and measurable financial returns.

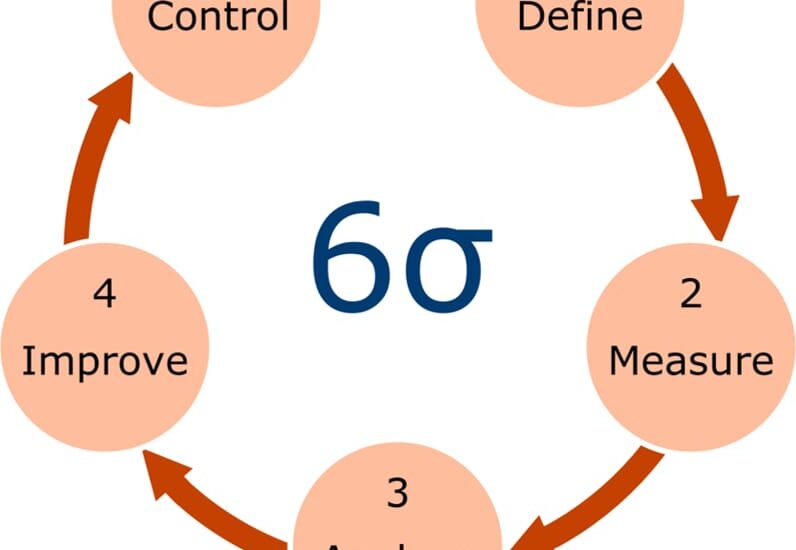

This emphasis on quantifiable results appeals to executives who want concrete evidence that improvement efforts justify their investment. But honestly? It also appeals to me. I like knowing whether something actually worked. The most widely used Six Sigma methodology is DMAIC, which stands for Define, Measure, Analyze, Improve, and Control.

I have come to appreciate how DMAIC forces rigor at every stage. Too many improvement efforts jump straight to solutions without truly understanding the problem. We see this constantly when someone declares we need new software or we should reorganize the department. But what if the problem is not structure or tools? DMAIC prevents this mistake by requiring thorough analysis before implementing changes. When you must identify root causes with data rather than intuition, you often discover the real problem differs from assumptions.

I once worked with a team convinced that shipping errors resulted from employee carelessness. The Define and Measure phases humored this theory. But the Analyze phase revealed something else entirely: the warehouse layout placed similar-looking products on adjacent shelves with nearly identical serial numbers.

The solution was not retraining or discipline. It was better visual management and spacing. Without DMAIC, we would have blamed people rather than fixing the system. Six Sigma also professionalizes quality management through its belt system borrowed from martial arts. White belts possess basic knowledge.

Yellow belts assist on projects. Green belts work part-time on projects. Black belts manage Six Sigma projects full-time. Master Black Belts supervise multiple projects and mentor lower belts. This hierarchy creates career paths within quality management. I confess I initially rolled my eyes at the belt terminology.

It felt performative. But I have since observed that the certification structure provides something valuable: common language and recognized competency. When someone introduces themselves as a Black Belt, I know they have completed projects and passed examinations.

There is accountability baked into the credential. The methodology originated in manufacturing but has spread across industries. Healthcare organizations have used DMAIC to reduce medication errors and decrease patient wait times. I read about a hospital that cut emergency department boarding times nearly in half using nothing fancier than process mapping and variation analysis.

Financial services companies apply Six Sigma to streamline loan processing. Government agencies use it to improve service delivery. The tools are not industry-specific. They work anywhere processes exist. Critics argue that Six Sigma can become overly focused on incremental improvements while missing opportunities for radical innovation. I think this criticism has merit.

Some organizations implement it too rigidly, applying DMAIC to every problem regardless of whether the situation requires such intensive analysis. Not every issue needs a full-scale project. Sometimes you can just fix what is broken and move on.

Despite these limitations, Six Sigma provides valuable tools for organizations serious about quality improvement. The methodology has endured for nearly forty years because it works. Projects that follow DMAIC generate measurable results rather than temporary fixes. I have seen cost savings that directly impacted profitability.

I have seen customer complaints decline. I have seen teams solve problems that lingered unresolved for years. I now understand that Six Sigma is not corporate jargon but a disciplined approach to solving complex problems. The structure enables teams to tackle issues that have resisted simpler solutions.

When you need to reduce defects or improve process performance in demonstrable ways, Six Sigma delivers results. It does not require blind faith. It requires measurement, analysis, and the humility to let data challenge your assumptions.

References

American Society for Quality (ASQ). DMAIC Process: Define, Measure, Analyze, Improve, Control. https://asq.org/quality-resources/dmaic

National Center for Biotechnology Information (NCBI). (2023). Six Sigma Method. StatPearls. https://www.ncbi.nlm.nih.gov/books/NBK589666/

PMC. Define, Measure, Analyze, Improve, Control (DMAIC) Methodology as a Roadmap in Quality Improvement. https://pmc.ncbi.nlm.nih.gov/articles/PMC10229001/

GoLeanSixSigma.com. (2025). DMAIC – The 5 Phases of Lean Six Sigma. https://goleansixsigma.com/dmaic-five-basic-phases-of-lean-six-sigma/